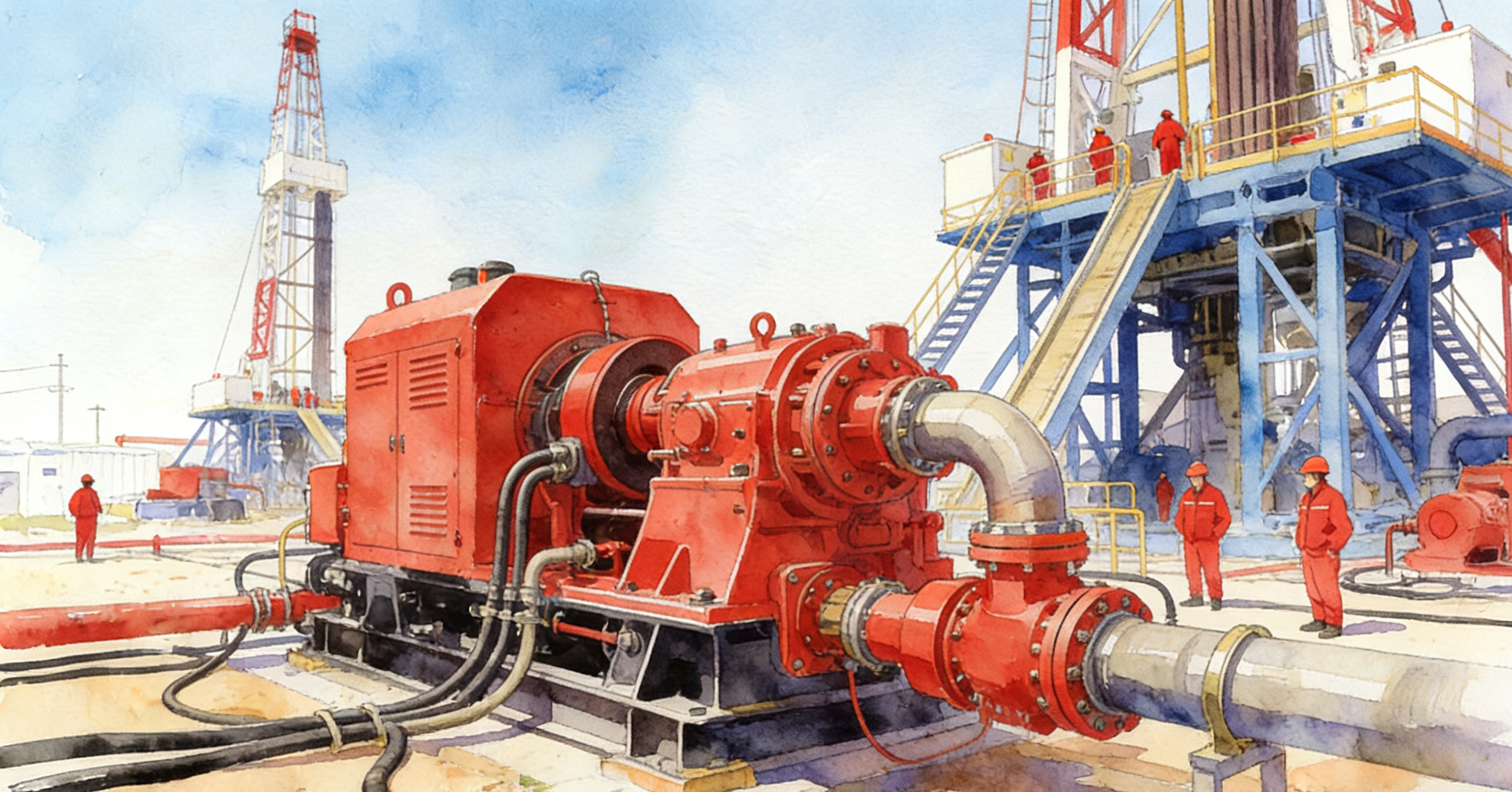

In today’s oil and gas industry—particularly in unconventional shale development “efficiency” is not just a buzzword; it is a rule of survival. With extending lateral lengths and increasing stage counts, job sites are imposing unprecedented challenges on hydraulic fracturing equipment, especially the Frac Pump, known as the "heart" of the frac fleet.

As a manufacturer specializing in high-end fracturing equipment, we understand that for oilfield service companies, the initial purchase price is merely the tip of the iceberg. The Total Cost of Ownership (TCO) over the equipment's lifecycle is the true determinant of profitability.

Today, let’s discuss why upgrading to high-performance fracturing pumps is the optimal solution for reducing TCO.

1. Conquering the Extreme Challenge of "Continuous Duty"

Past fracturing operations might have allowed for intermittent equipment downtime, but in today’s "factory-mode" drilling and completion environment, 24/7 continuous operation is the norm. Under high-load continuous running, standard pumps often face:

Fluid End Cracking: Inability to withstand high-frequency cyclic stress.

Power End Overheating: Inadequate lubrication and heat dissipation design.

Once the "heart" arrests, the Non-Productive Time (NPT) costs for the entire frac fleet accumulate by the minute. High-performance pumps, utilizing reinforced crankshaft alloys and optimized stress distribution designs, ensure thousands of hours of failure-free operation even under full-load conditions.

2. Adapting to Harsher Media: From Slickwater to Highly Abrasive Quartz Sand

To pursue higher production rates, proppant concentrations in fracturing designs are constantly rising, with an increasing shift toward highly abrasive quartz sand. This tests the pump's expendables to the limit.

A premium frac pump does more than just deliver pressure; its value lies in whether its internal Valve Covers and Plunger coating technologies can resist erosion. For instance, fluid ends with special surface hardening treatments often boast a lifespan 2-3 times that of standard carbon steel products, translating to lower replacement frequency and reduced expenditure on consumables.

Conclusion: More Than Equipment, It’s Productivity

Selecting a frac pump is, in reality, selecting a guarantee of productivity. At Victory, we are committed to providing fracturing pump solutions that benchmark against world-class standards through innovative manufacturing processes. Whether facing ultra-high-pressure deep wells or adapting to long-duration electric fracturing operations, we have one goal: to ensure every drop of fuel or kilowatt of electricity you spend is efficiently converted into fractures deep within the formation.

Victory — Your Partner for Next-Generation Fracturing Power.